For this design project, we had to create a solution for a cheap, easily distributed, low payload air-droppable disaster shelter that had be easily or automatically deployable. These were to be designed for mass manufacture and to be used primarily in developing nations in massive disaster events. Language differences and potential illiteracy was to be taken into account.

My team began by outlining and prioritizing the problem's design constraints. We felt that the most important criteria were collapsibility/packing efficiency and instant deployment and usability.

We found inspiration in airplane emergency inflatable slides and life jackets, automobile air bags and sun shades, insulating foam, and collapsible laundry hampers. Driven by cost and deployment speed, we decided to build on the laundry hamper and sun shade ideas, and created this concept:

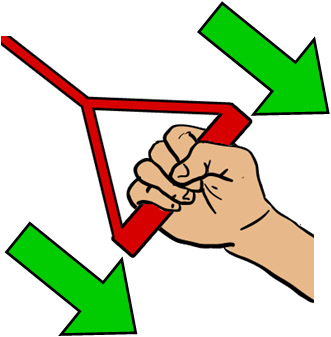

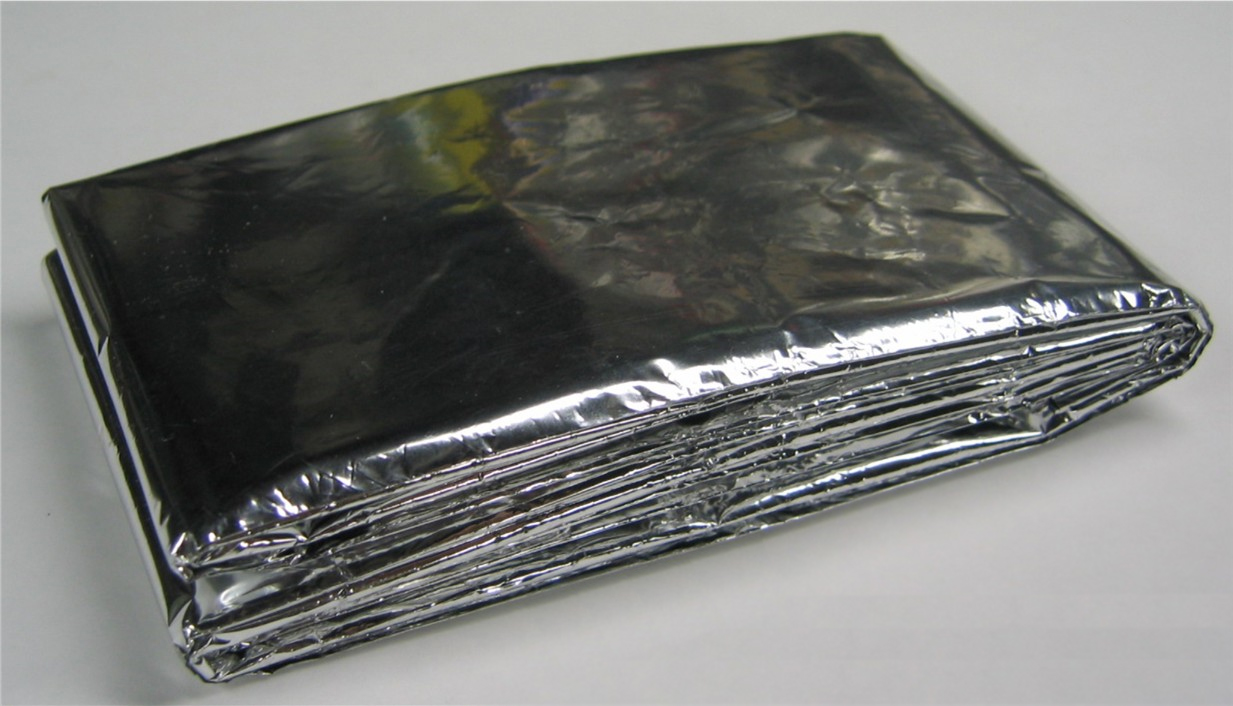

Our concept would be palletized and air-dropped in a disaster zone, where a user would be able to easily transport it to the desired location. Once there, a simple tug on a cord would release folded spring steel hoops that would pop up to form the structure of the shelter. The walls of the structure, a heat-reflective Mylar-like sheet, would unfold with the hoops.

Deployed, this half-domed structure would accommodate a family of 4, although it would also be able to collapse to nearly 5% of its deployed volume for efficient packing and shipping.

Rapid prototyping was the primary focus in this exercise, and as such, we created a wide variety of mock-ups, ranging from small wire and fabric disks illustrating the unfolding process to a full-scale walkthrough model that allowed us to visualize the actual space.

We were pretty pleased with our concept, and felt that it successfully addressed the problem. Aided by our successive iterations of prototypes, we achieved our goals of maximizing the shipping/packing efficiency, minimizing the deployment